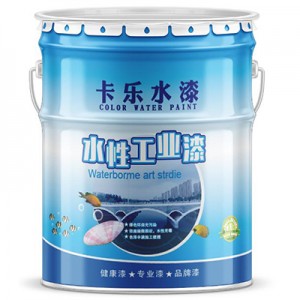

Single Component Building Roof Acrylic Waterproof Coating Waterborne single component varnishes

Application

Product Description

Feature

1.Super bonding strength.

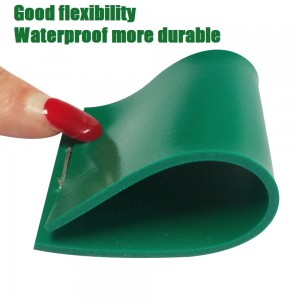

2.Good flexibility,can fill flaws.

3.Have good coated water proofing,mould proof,ware proof,ageing resistant,and don't need to do protection after painting.

4.Can work on wet surface.

5.Non-toxic ,meet environmental requirements.

Quick Details

| Product Name | New Waterborne Polyurethane Waterproof Coating |

| Product Manual | a single-component polymer liquid curing type elastic waterproof coating material. The product does not contain solvents, cold construction, non-toxic and odorless, has good adhesion and water impermeability, has strong adhesion to the cement and concrete base, stone, metal products, chemical stability of products, energy Long-term exposure to sunlight, high strength, high elongation, good elasticity, good waterproof effect, the coating can be cured to form a layer of dense, strong, flexible waterproof coating at the base level, high tensile strength, excellent extensibility, Strong ability to adapt to deformation of base surface, good low temperature performance, and construction of water-based polyurethane waterproof coating is extremely simple, without any pollution, has the advantages of high performance, wide use, and multi-functionality; product has excellent elasticity, outstanding outdoor durability and resistance UV performance. |

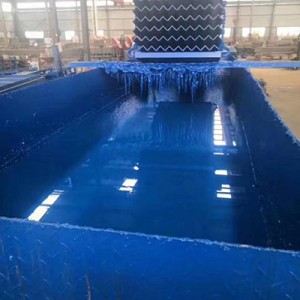

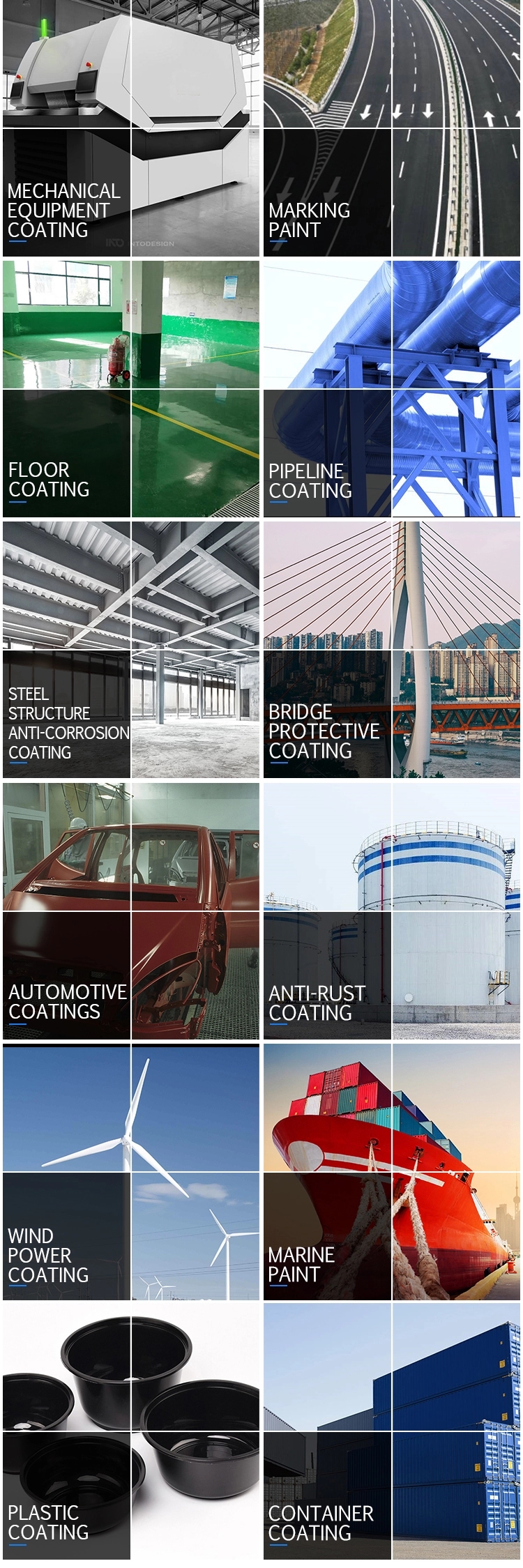

| Scope Of Application | 1. Widely used in waterproof and moisture-proof engineering of new and old roofs, color steel tile (metal roofing), factory buildings, basement, tunnels, bridges, culverts, and civil defense projects 2. Plane, facade, internal and external walls, and direct exposed waterproofing 3. Bathrooms, kitchens, bathrooms, balconies, bay windows, swimming pools, waterproof seals for internal and external walls 4. All kinds of underground fire pools and waterproofing projects with poor ventilation |

| Features | 1. One-component, cold construction, safe and simple, easy to construct, a solid polymer product 2. It can be applied on wet (non-clear water) or dry base surface, with strong adhesion to the base layer, and the coating has wide adaptability to the base layer. 3. for concrete, masonry, mortar, metal, wood, glass, ceramics, plastics, insulation and so have a 4, green, solvent-free, non-toxic, odorless, no pollution to the environment 5. coating tensile strength, extensibility (elongation 300%) The waterproof layer has good integrity and adapts to the cracking deformation ability of the base layer. 6. super adhesion, high solid content, small amount of use per unit area, cost-effective 7. excellent cold resistance, chemical resistance, anti-aging properties and mold performance is superb. |

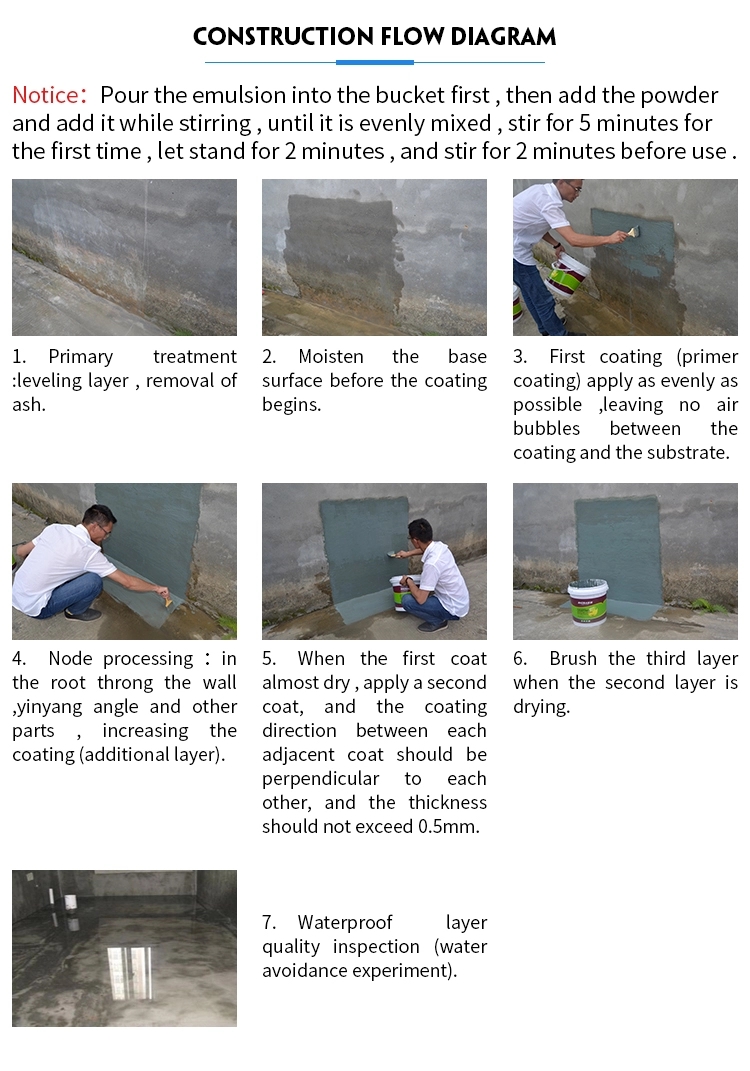

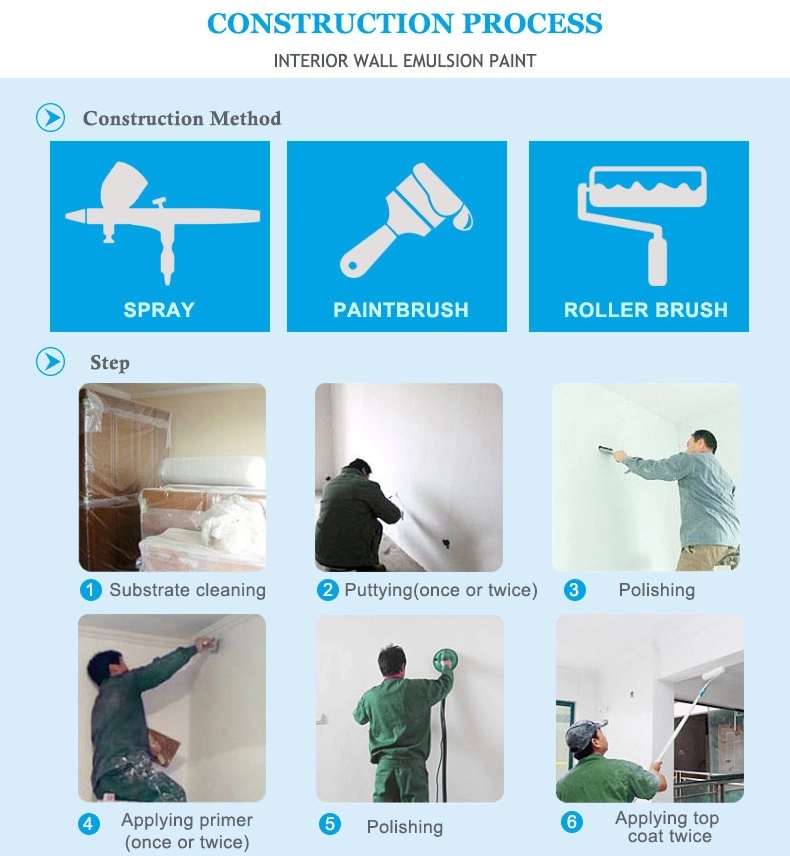

Note:The base layer must be treated before construction.

The base surface is required to be flat, solid, dust-free and oil-free.

There is no isolated media attachment.

Holes and ductile cracks need to be repaired, and the yin and yang angles are first treated as arcs or obtuse angles.

If the base layer is dry, it is preferred to use water to fully wet to no water.

1. Product characteristics

| Fast drying, good adhesion, excellent resistance to UV

Good outdoor durability, lower temperature application Excellent abrasion resistance |

2.Product usage

| Mainly used as traffic line or marking paints of roads, cement or asphalt road surfaces. |

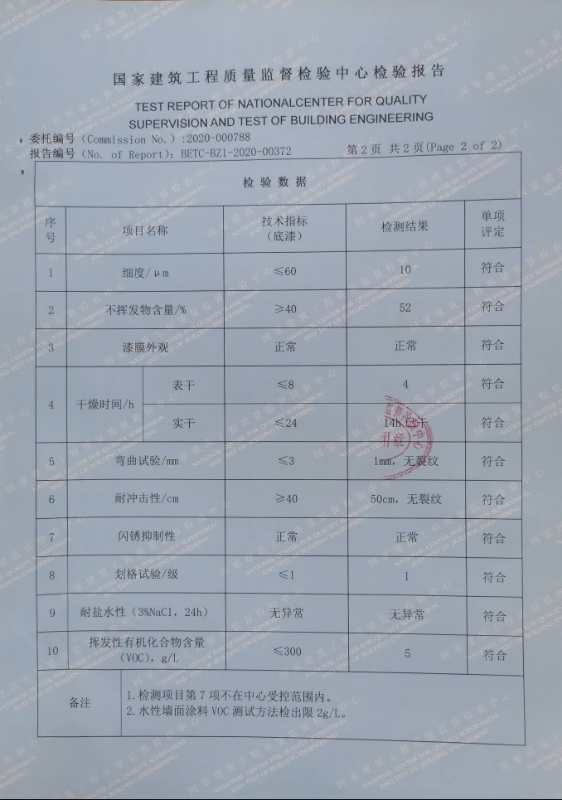

Product technical parameter

| Name | Acrylic Acid road marking paint

|

colour | White, yellow or all colors |

| Technical parameter

|

Mixing ratio: One component

Standard film thickness: Dry film thickness: 80μm/coat Wet film thickness: 125μm/coat Academic spreading rate: 0.25 kg/m2/80μm 0.179L/m2/80μm Solid contents: 60% Humidity requirement: below 85% Specific gravity:1.4 |

||

| Substrate treatment

|

Thoroughly clean the road surface free of dust and miscellaneous soil, and keep the surface dry.

Stir well before application. Maintain half to one hour after application prior to use. It is forbidden to be mixed with water. Do not apply under rain, wind and dust . |

||

|

Matching

|

Preferable substrates: cement or asphalt road. If you have any doubt, please refer to JINHAI PAINTS | ||

| Drying time & Coating interval | Temperature(℃) 10℃ 20℃ 30℃

Dry to touch 25mins 15mins 10mins Dry semi-hard 1hrs 0.75hrs 0.5hrs Min. interval 2hrs 1hrs 1hrs |

||

1. OEM service.

2. Technical support if your order is large enough.

3. Exchange and refund service if our products have quality problems.

4. Assured quality, reasonable price and perfect after-sales service.

5. 24 hours on line for your reference.

1. Can you provide some free samples?

Yes, free sample is available.

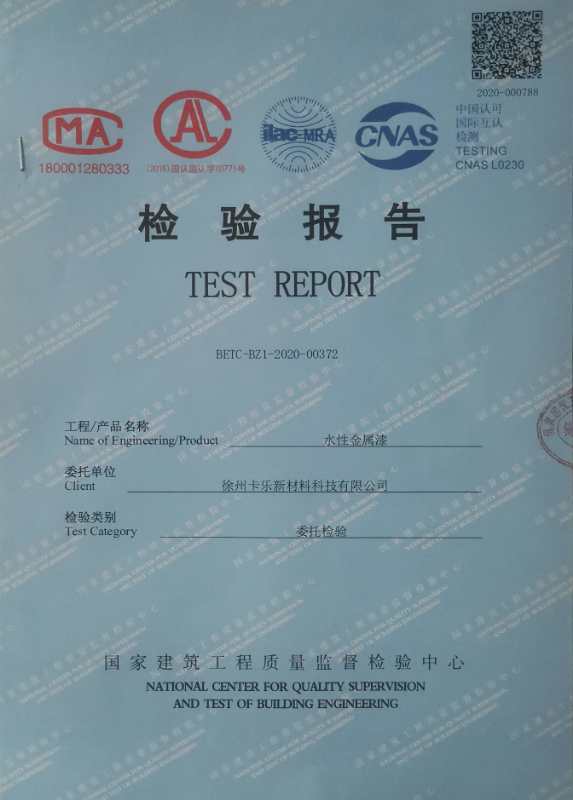

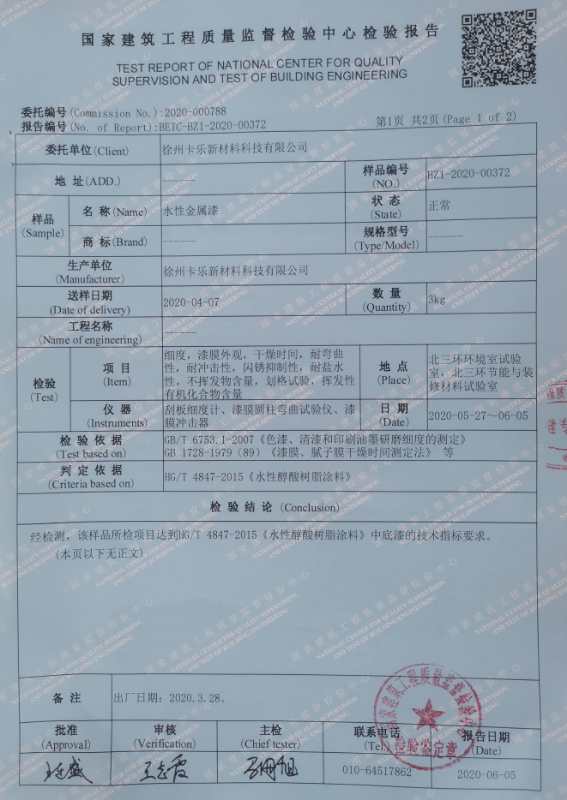

2. How do you make sure the high quality?

We have strict product quality control testing.We also have got the ISO9001

quality management system certificate and BV certificate.

3. Who is your main customer?

We export to more than 50 countries, such as Oceania, MiddleEast, North

America, South America, Eastern Europe, etc.